With sneaker culture bigger than ever, the designers behind some of the most iconic shoes of all time are gaining celebrity status; sometimes more so than the athlete that originally endorsed (or currently endorses) the shoe. These footwear Picasso’s have traveled the world, worked with some of the greatest athletes of all time and created functional art that’s adored by millions. Names like Tinker Hatfield, Paul Litchfield, and D’Wayne Edwards are familiar but today DeFY. is going to introduce you to another design legend. His name is Steven Smith. This 27 year footwear industry veteran has worked at New Balance, Adidas, Reebok, FILA, Nike and is back at Adidas. His portfolio reads like your christmas wish list and includes: The New Balance 574,576, 996, 997,1500, and NBX (as well as a few others from New Balance), the Adidas Artillery and the Phantom 2, a majority of Nike’s Bowerman product from 2000 to 2006, Cage Zoom Spiridon, Shox Monster, Monsterfly spike, Air Max 2009, and last but not least the Reebok Pump Fury (which by the way, is in the London Design Museum). Oh yea, and he was also part of the team that created what we all know today as Reebok’s Pump technology. DeFY. New York recently had the pleasure to sit down with Steven for some Q & A’s check it out!

Hey Steven, I appreciate you taking the time out of your hectic schedule to sit down with DeFY.

DeFY: When did your passion for design start?

Steven: Pretty much from when I was a little kid. I always wanted to know how things worked and how to improve them. I also was lucky enough to go to an elementary school co designed by Walter Gropius the former head of the Bauhaus.

DeFY: What was your first pair of sneakers?

Steven: My first pair was most likely my SL 72’s then Adidas Countrys.

DeFY: A lot of designers I’ve spoken with have a bunch of old shoes laying around the house but don’t really consider themselves collectors. Do you actually go out and buy new/vintage sneakers to collect?

Steven: Yes I do collect. Actually, what a lot of people have been doing the past decade, combing through the mom and pop stores, I did that in the late 80’s early 90’s before most people were really sneaker collecting.

DeFY: What sort of treasures were you digging up?

Steven: Original Nike Waffle Trainers and Roadrunners for like 10 bucks. One thing that will make you cry, there was this crappy close out store across from Reebok and they had pallets of original Jordan 1’s for 14 bucks a pair, full size runs. So I was like you know, Im a running guy, thats my sport and I’m like ahhh basketball I’m not really interested, then I thought I should have bought one pair now I’m like $%#$ I should have bought them all!

DeFY: Haha! Yea I actually remember finding a bunch of 1970’s made in the U.S.A. Converse’s at this shop in Brooklyn for 5 bucks a pop no original box, I bought whatever was left! So what gems have passed through your collection?

Steven: Well I just recently sold off a pair of New Balance Tracksters, I had a bunch of earlier New Balances and Montreal Nike’s, Nike Huaraches. At one point I had around 350-400 pairs but I’ve sold off about 160 pairs the past few years.

DeFY: When did you get your start in the footwear industry? What was the first sneaker you designed?

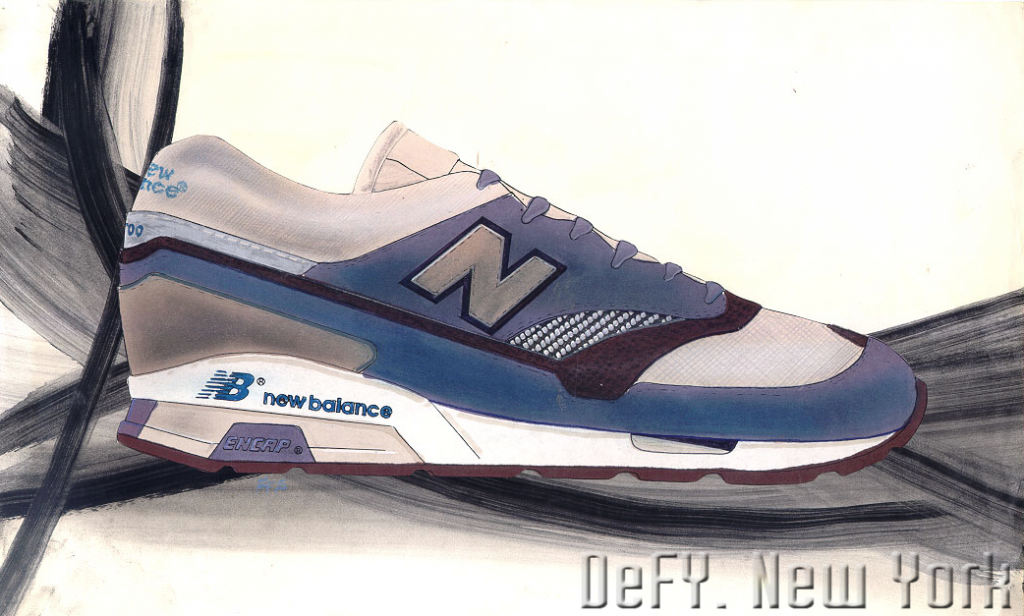

Steven: I started at New Balance in 1986 right out of college. One of the first running shoes I worked on was the 574 and the 995, then came others like the 1500.

DeFY: Were you involved with any basketball shoes at New Balance? Why do you think New Balance wasn’t able to sustain their presence in that market?

Steven: When I arrived at New Balance, there were only 3 other designers in the history of the company. Me and a guy named Kevin Brown designed everything for them during that period and that included the 428 as well as a shoe called the NBX.

I think New balance never really took off for basketball because they didn’t want to advertise and basketball was all about advertising and getting the athletes. They had Worthy and he was a great player, but he was an in the background type of guy not like a Jordan or Barkley that was in your face.

DeFY: During the design process, how do you balance fashion with function?

Steve: I was always focused on the function first and the fashion would be a result of the performance solution. They are really intertwined. I never set out to create Industry Icons it just so happened the insights were correct.

DeFY: How do you approach a new design?

Steven: The way I always look at it is that, I have 100 bucks and I have a kid and what else can he get for 100 bucks. I have to create something more compelling that this kid wants to spend his 100 bucks on vs an iPod, whats cooler? Thats the way i approach it all the time.

DeFY: Is there ever a time you feel uninspired? If so how do you overcome that?

Steven: I do. I usually find inspiration through my running and my hobbies. I love machines and vehicles. The best is still getting out for a good 5 miler. It really allows me to focus on the project.

DeFY: With sneakers being a part of our every day lives how do you balance work with downtime without the two overlapping or can you?

Steven: You never stop designing and thinking about design. I am always looking for new things. Sometimes you wake up in the middle of the night and have to sketch something out.

DeFY: Is there a shoe that you didn’t design that you wish you had?

Steven: I think the two are the Gazelle and the Sock Racer.

DeFY: What are your favorite sports?

Steven: Running and Vintage Car Racing. Motocross is right in there in the mix though.

DeFY: Of all the projects you worked on which 3 are you most proud of and why?

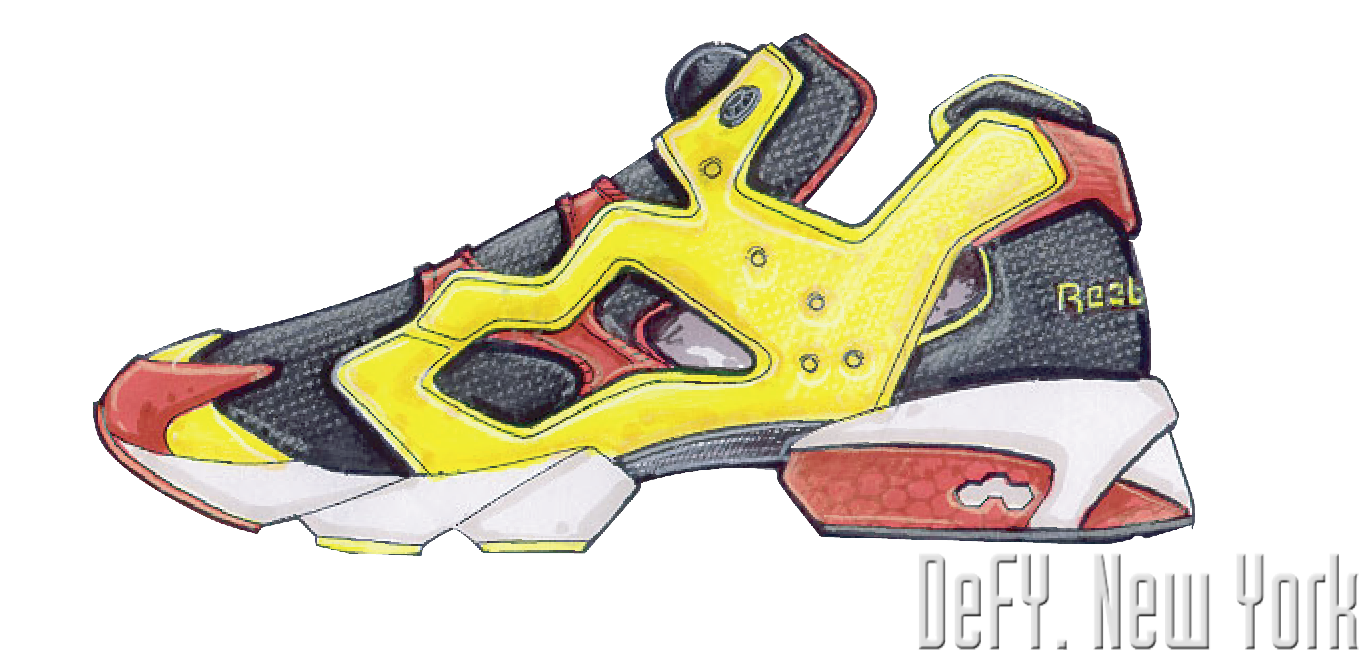

Steven: I think the 574 due to it’s longevity, the Reebok Pump Fury due to the fact that there has still been nothing quite like it and the Mi Coach Elite Team system that I have been designing on for the last two years.

DeFY: You designed some of the greatest running shoes of all time; the New Balance 1500, 996,997, 576, Nike Air Max 2009 and the Reebok Pump Fury. All of them are fairly reserved in their design aspect with the exception of the Pump Fury. What was your inspiration for the design of the Fury and why the change in direction from “safer” more “consumer friendly” design to in your face and youthful? Did you have a tough time convincing people internally to get that shoe to market?

Steven: The Fury was a vision. It took an endless amount of internal wrangling to execute it as sketched because people were scared of it. They would say “don’t cut it all the way through cut it only half the way through.” Before the Fury though, I designed a shoe called the Graphite Road.

That was the first use of the carbon fiber arch. You see, as a company gets bigger and more conservative they aren’t willing to take risks and leaps of faith and I had a difficult time with marketing. By it’s nature, Reebok was a very conservative company at the time. Nike looked at the Max franchise as a cash generator. Each product is unique to it’s particular brand ethos and we decided we were going to beat them at their own game and upgrade the limits of what technology could be by going head to head with the Air Max and thus I designed the Fury. Paul Fireman excelled at this and gave me the power to do that shoe, it was our “middle finger” to Nike. An interesting fact, the Fury was a tribute to the shoe I always wanted as a kid which was the New Balance Super Comp.

That was the prime shoe, it looked like your foot was on fire! So I wanted to do a futuristic tribute to that shoe and make your feet look like they were on fire.

DeFY: Take us back to the beginning of the Fury, when did the project start and how did it evolve?

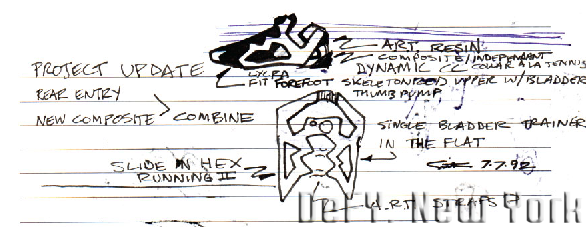

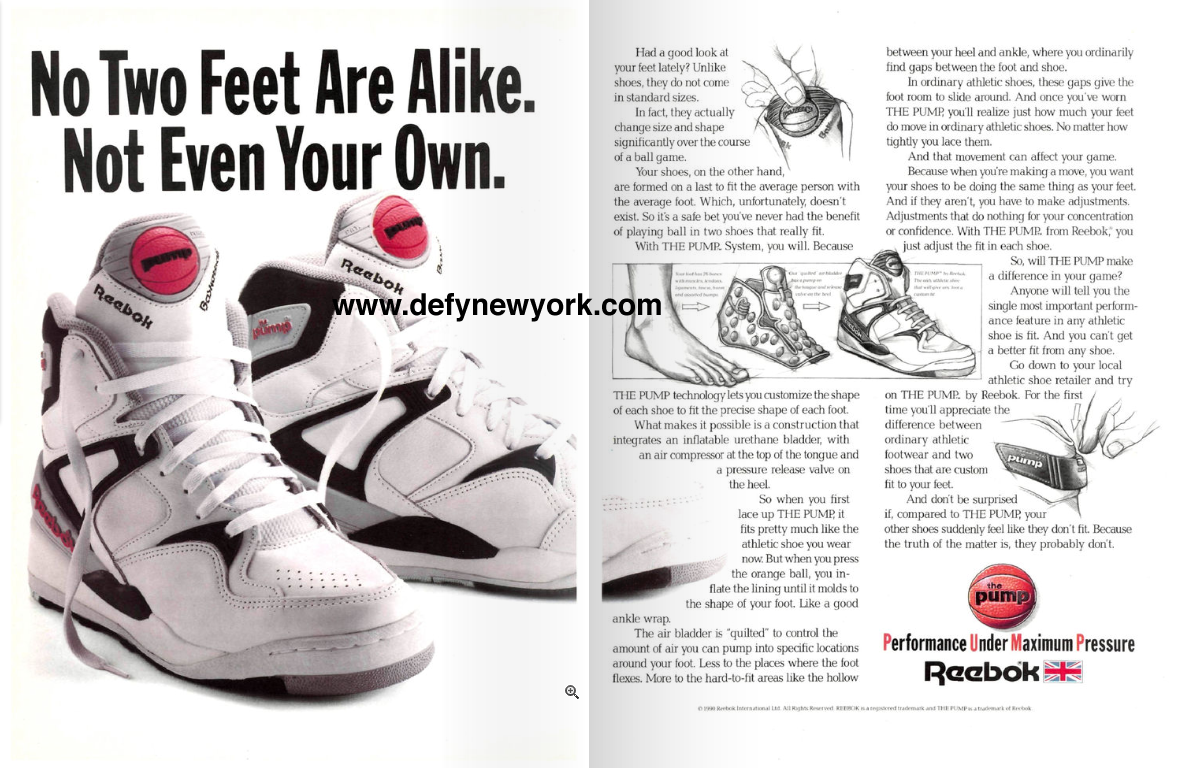

Steven: The story of the Pump Fury begins in 1992. Reebok had allowed Steve Burris to assemble its first Innovation department two years earlier. At the beginning, it was Steve as the director, with me as the Senior Designer and Peter Foley and Paul Litchfield as the Senior Developers. We were operating as the “blue sky” think tank for the company. All of us had pretty diverse backgrounds in the sporting goods and footwear industry, and that eclectic mix of talents and knowledge helped us create some pretty impressive technology for such a small team.

At this point, our team had already been instrumental in the rollout and expansion of the Pump product as well as exploration of Hexalite cushioning. For our next project, we had some cool ingredients for lightweight construction and improved cushioning, but we also wanted to do something dramatic with the Pump technology. After some brainstorming as a team, we thought “hey, why not combine a few of these great ideas into one showpiece of footwear” – sort of like a “concept car” for all of our innovation projects. I was fired up and started sketching right away. Earlier, when were developing the Graphlite carbon arch, I had done a sketch with the midsole cut in two, with the carbon unit acting as an architectural bridge between the forefoot and heel. Peter was the developer covering Hexalite and Graphlite projects, and he was excited to try to build that original vision. Lichfield was responsible for Pump technology, and had an idea to bring the fit system to the outside of the shoe instead of the inside – making it into a sort of exoskeleton. Another technology we wanted to include had the working name of “slide-in hex” – a specially-engineered, vertical version of Hexalite for use in the midsole. This would later find its way into the Question basketball shoe.

DeFY: How did you keep other brands from basically stealing your design/idea?

Steven: Well, I liked to have fun with my projects and always gave them silly working names. This also helped to keep Nike’s APE team off our trail in the Asian development centers. I was on a trip to Korea and saw a Daewoo car called the Maepsy. I thought it was pretty silly, so that became the working name for the shoe. Peter liked a good joke too, and the name stuck. In fact, Daewoo developed a special mesh for the Pump Fury project and ended up calling it Maepsilon, and it became part of their product line!

DeFY: Wow, haha! Funny how things work out. BTW I think I might start referring to my Fury’s as the Maepsy’s!

Steven: Haha! This was such a challenging project, actually one of the most challenging projects we ever worked on. Peter spent a good deal of time working with aerospace suppliers to fabricate the carbon fiber arch bridge. Litchfield and I focused in on the external pump system. We had this vision of a shoe where the pump would be the sole method of adjustment. If you look at the shoe and you fold down the heel and the tongue, you’re left with an inflatable exoskeleton.

DeFY: I’ve read that getting the pump to function properly in the original basketball pump was difficult was it easier this time around?

Steven: No, Making a functional exoskeleton was difficult. We were working with the textile manufacturer to develop a knit that could expand with inflation, yet also protect the film airbag inside. The first versions we built just kept expanding and pushed off the foot – not the best thing for fit. While working with Shawmut Mills, the light bulb came on; why couldn’t we engineer the film and fabric to expand on the outer surface to a certain point and then lock out, while the internal surface kept inflating around the foot? This is how we did it. The external fabric allowed 10 percent expansion and then the knit would lock out. The internal fabric was allowed to keep expanding around the foot to create a snug, balanced fit. Samples were made and it worked! As the sole units started to arrive, we assembled the first samples and stepped back to take a look. It was a pretty radical combination of elements. We couldn’t wait to show it to Paul Fireman – CEO of Reebok. Off we went to the top floor of the main building. After a quick hello to Paul’s super admin, Julie Frasier, we went into the big boss’s office. Let’s just say he loved it. The next question from Fireman with our projects was always “Can we have it now?” Uh oh! It’s really going to get busy now! “Um, uh, sure Paul – whatever you want!” He did after all control our budget and clear the way for us to operate as think tank. Oh yeah, and he owned controlling stock in the company.

DeFY: Ok so the big boss loved it then it was smooth sailing from there no?

Steven: Not quite. The biggest challenge and battle lay waiting for us. How do you integrate such a radical product into the commercial running line? Since Peter had lived in product marketing earlier in his career, he was ‘elected’ to be the point man for this one. He took it over to the inline marketing team to introduce the shoe to them. Needless to say, it scared the crap out of them. “We don’t have a place for it, sorry.” Well tough, Paul Fireman wants it in the line and, that would be NOW. Then the enemy of innovation – conservatism – came out for a visit. “Well, we will take it but only if it’s neutral gray.” When Peter came back from the meeting and told me that, I was pretty pissed. I took the sample and sprayed the entire thing auto primer gray and said “go tell (unnamed marketing manager) to stick this up his a$$”. Peter was cracking up. It was pretty obvious that the shoe was not nearly as exciting in all gray. We both went back over to the marketing department with the all-gray and red-yellow-black versions, and the response was “now that’s what it needs to be”. I, on cue, responded “that’s BS!” From there, the discussion degenerated to “if you don’t take the original colorway, you can’t have it at all and you can to explain to Paul Fireman why”. The next volley was that same marketing manager saying “Ok, we’ll take it, but you watch, the gray colorway will be the lead at 60 percent of the volume to 40 percent for the red-yellow-black version.” I replied, “yeah we’ll see!”

It turns out, he was right about the numbers, but wrong about the colors – the red-yellow-black version of the Pump Fury outsold the gray version 60-40. It went on to win the Popular Science “Best of What’s New” award and was featured in the London Design Museum. And nearly 20 years later, the Pump Fury is still in the Reebok product line.

DeFY: Awesome! I think I speak for everyone in the shoe community when I say thank you for fighting for that colorway! What are some of your fondest memories tied to the Fury?

Steven: Well, once we had to make a size 23 Fury for Shaq which was pretty funny. He came up to Reebok one day with his mom and dad and his mother was the only one that could fit what we had. So she tried them on and he loved them. At the time we were making The Pump bladders in Chicopee Massachusetts and I remember the machines not being able to make a bladder big enough for his size, they were really hard and expensive to make.

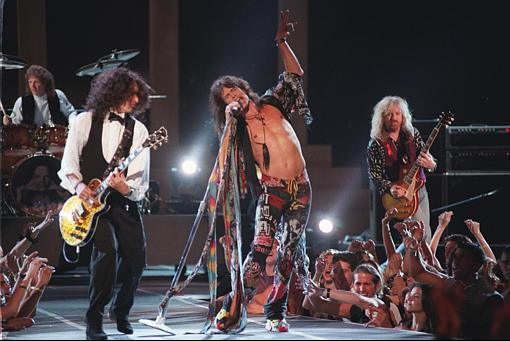

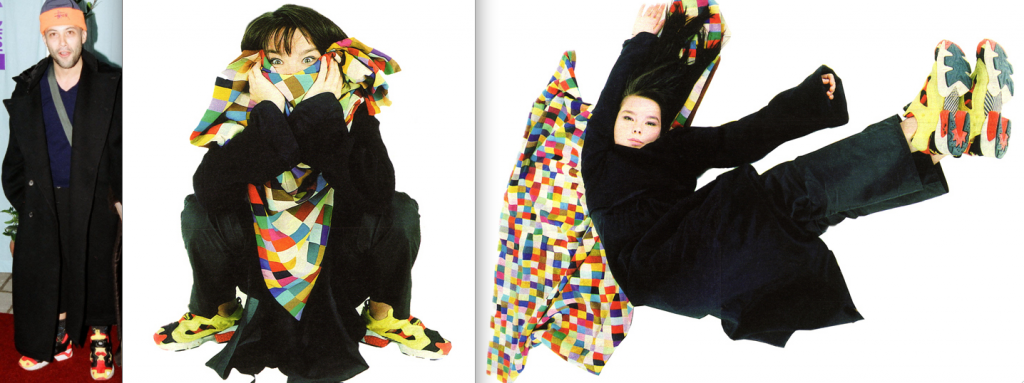

I think my favorite memory though is when Steven Tyler performed at the 1994 MTV Music Awards with Aerosmith while wearing the Fury. See, today, people in Hollywood are given those things but back then Steven Tyler actually went out and bought them (it wasn’t like Reebok sent them to him).

A friend of mine (Rick Nielsen of Cheaptrick) eventually introduced me to Steven Tyler and I go “dude you wear my shoes!” and then Steven goes “man those things got me through the 90’s!” it was awesome, and I’ve been friends with him so its been fun. It was also great to see Bjork and Stephane Sednaoui wearing the Fury too.

DeFY: Sneakers are being retro’d over and over and over again with the companies making a boat load of money. Do you guys receive royalties from your old designs?

Steven: I wish! Unfortunately no. I (and most designers) didn’t create these shoes to think that the shoe would be popular in 10 years, I tried to create the best shoe at the time.

DeFY: It seems that companies have spent hundreds of millions of dollars on research and development for technology to soften the blows that our feet take but now barefoot running or shoes that mimic it are becoming increasingly popular. Do you think this trend is a threat to the industry?

Steven: I don’t . Barefoot shoes are not for everyone though. The foot is an amazing series of complex mechanisms to do just what we try to do with the shoes. That is why there is still no good computer simulation as to how a complete foot structure works. Due to our man made environments we created the need for protective foot coverings.

DeFY: How often do you travel overseas to the factories? What goes on during these visits?

Steven: I used to go 5 to 6 times a year for 2 week stints. Now we spend less time in the factories and more time out with the customer. Most trips were to introduce the project to the development centers and then follow up trips to check progress and institute any revisions or changes. You work directly with pattern makers and mold shops to get all the details executed correctly. Usually it was up at 5:30 get a run in and then off in a one hour plus car ride to the factory. Then your wrapped up by 7 headed back to the hotel for a late dinner and then faxes and emails to the home office and then repeat again the next day. The downside is you don’t go home to your family at the end of the day.

DeFY: Are there any shoes that you worked on that never made it to retail but felt they should have?

Steven: Lot’s of them. There was a really cool smart ‘computer controlled’ shoe that Litch and I worked on. It is still pretty amazing today.

DeFY: You worked on The Pump technology with Paul Litchfield and during that time, other brands like Nike, L.A. Gear and even Spalding were coming out with pump shoes. What runs through your mind when you see other brands bringing to market technology that you helped evolve and develop?

Steven: It is frustrating to see all the hard work ripped off. Also that we made all the pump devices in the US and all the knock offs were made in Asia. I liked bringing some manufacturing home to the US. The copy cats also gave validity to the concept that it was right.

DeFY: Last year I interviewed a gentleman that developed (and is currently selling) 100% recyclable sneakers. So far I’ve seen the big brands manufacturing sneakers that boast of environmentally friendly materials and box’s but not 100% recyclable. Is this something we might see in the near future? If not why?

Steven: Yes. It is a growing priority for the industry. Key issues are the technical nature of what we create and the durability consumers have become accustomed to. It is easy to make a pair of Tom’s eco friendly but just try it with a D. Rose or highly technical product.

DeFY: What’s the biggest thrill you experience as a designer?

Steven: As a product designer the biggest thrill is that you have your work appreciated by so many people. When i got out of school a bunch of other kids from my design program went to work as consultants for high tech companies in Boston like Corning Medical and I went off to New Balance. Those guys would go design a product that would be seen by like 20 doctors in the world but when I designed something millions of people all over the world would have them, so I could go anywhere in the world and see someone that spent the money on something that I did and said wow thats cool. This person in Tokyo, Korea or France saw that and said, you know what? Im gonna give up 100 bucks for that and you could go anywhere in the world and see them and its the coolest thing, it still is, to know that you did something that appealed to people all over the world.

DeFY: What are you currently working on?

Steve: Wearable Sport Electronics and a little Running for Adidas.

DeFY: What are some words of wisdom you can give to up and coming designers?

Steve: Perfect your drawing skills but always look for performance as your starting point. Just because it looks new doesn’t mean it is better. Stay with your dream. If you can dream it you can build it.